QM software from JAWA

Software for quality assurance and quality management

inforum from JAWA is the modular QM software with which companies can efficiently digitize their quality assurance. You benefit from a powerful platform that adapts flexibly to individual processes and bundles all relevant quality data centrally.

With inforum, FMEA, inspection planning, complaint and action management and numerous other functions can be mapped in an end-to-end QM system. This ensures greater transparency, fewer errors and sustainably higher product and process quality.

Your benefits with inforum QM software

All quality data in one place – from development to series production

Modular & scalable – choose only the modules you really need

Standard-compliant & audit-capable – supports ISO 9001, IATF 16949, VDA & other standards

Efficient processes – end-to-end digitalization and automation

Optimized supplier relationships – through transparent key figures and evaluation

Modules for your quality management

APQP & project management

Plan, manage and document projects efficiently – for smooth collaboration and transparent processes.

Audit management

Prepare, conduct and document audits professionally. Recognize deviations and derive effective improvement measures.

Task & action management

Clearly assign tasks, monitor progress and achieve sustainable improvements.

Control plan / production control plan

Plan quality assurance measures in a process-oriented manner, document them centrally and present them in a comprehensible manner at all times.

Initial sampling / PPAP / PPF

Identify potential errors before the start of series production and ensure standard-compliant processes.

Production testing / SPC

Plan and automate inspections in production and identify trends early on to avoid rejects and rework.

FMEA

Systematically assess risks and eliminate weak points at an early stage – for safe products and stable processes.

Supplier cockpit & supplier evaluation

Easily evaluate suppliers, compare key figures and ensure quality along the entire supply chain.

Test equipment management

Manage test equipment efficiently, ensure compliance with standards and reduce testing costs.

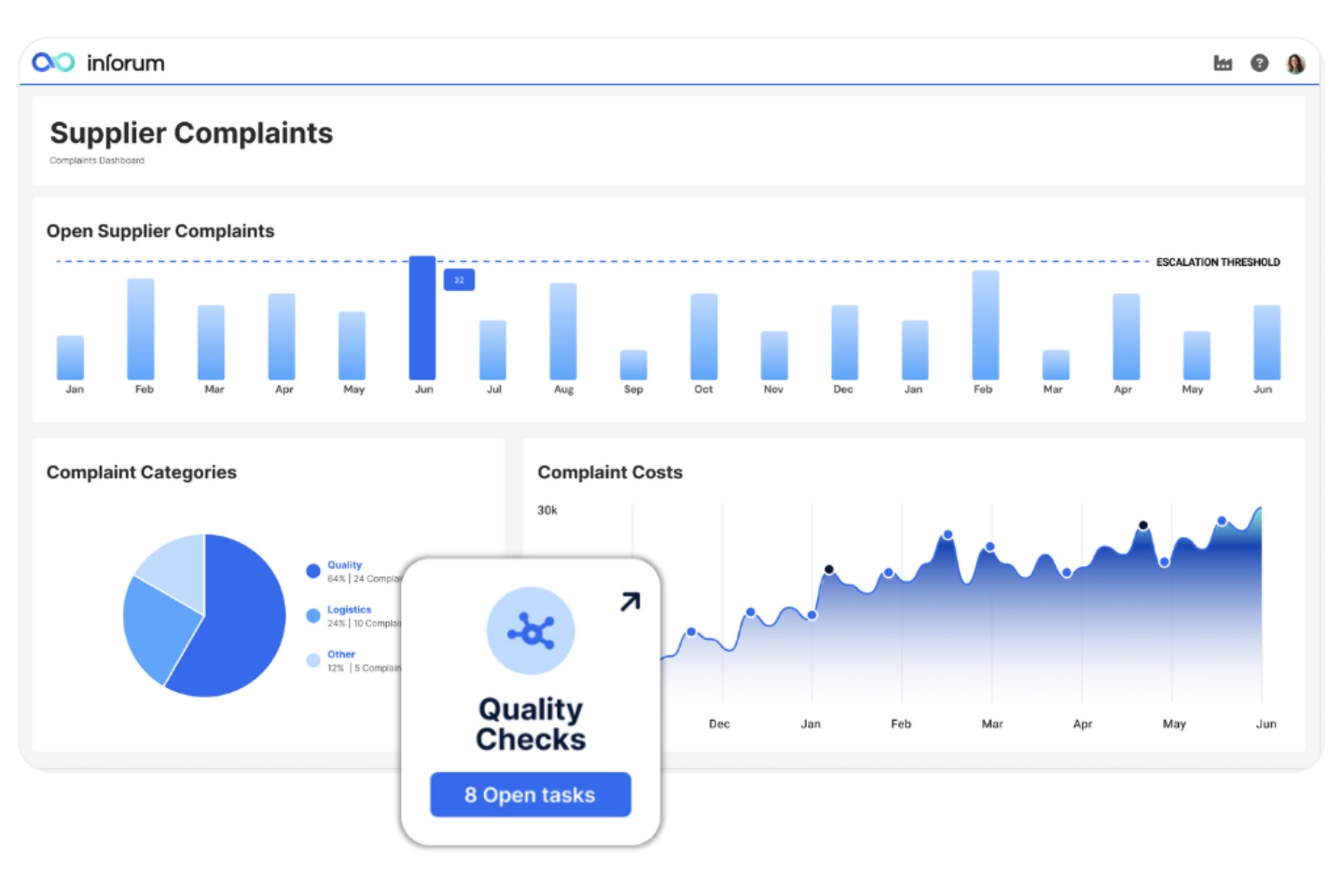

Complaints management (8D methodology)

Process complaints digitally, analyze causes and document improvements sustainably.

Preventive maintenance

Ensure machine availability, plan maintenance and avoid unplanned downtimes.

Incoming & outgoing goods inspection

Document incoming and outgoing inspections efficiently and make quality verifiable at all times.

Warranty Management

Evaluate warranty cases in a structured manner, determine causes and initiate systematic improvements.

Quality Cockpit

Keep an eye on all quality indicators in real time. Recognize trends, assess risks early on and make fact-based decisions.

Why companies worldwide rely on inforum

- Over 25 years of experience in industrial process optimization

- 100% Made in Austria – flexibly customizable and safe

- Ideal for automotive, mechanical engineering & other quality industries

- Integration into existing IT systems & individual customization possible

With inforum, companies build a future-proof, high-performance and perfectly tailored quality management system that creates both operational excellence and strategic competitive advantages.