Software for

Test equipment management

APQP makes it easier to plan quality, costs and deadlines, integrate suppliers and control the entire development process transparently.

Transparency, safety and traceability throughout

test equipment management

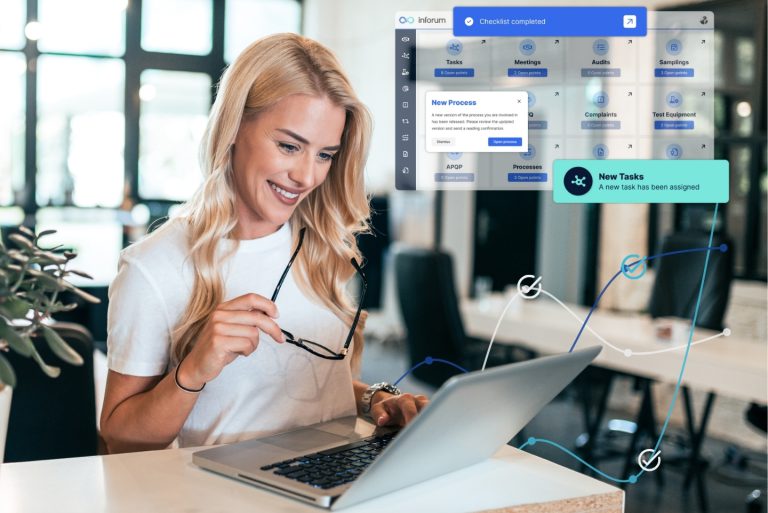

The test equipment management module ensures transparency, safety and traceability throughout the entire test equipment management process. It manages all information on devices, calibrations and safety tests centrally and supports compliance with legal and quality-related requirements – for maximum precision and availability of all test equipment.

inforum test equipment management

Compliance with legal requirements and quality standards

The system supports companies in consistently complying with legal requirements and quality standards – for example in accordance with ISO 9001 or IATF 16949. Regular safety checks and automated reminder functions prevent missed deadlines and increase operational reliability.

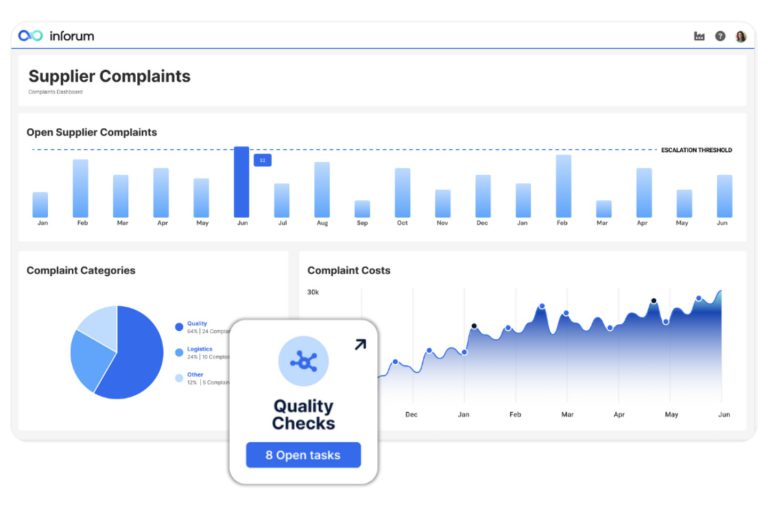

inforum enables the automated monitoring of all test equipment.

Test equipment monitoring from inforum

The automated monitoring of all test equipment is particularly efficient: sensor-based messages or system notifications detect deviations, impending failures or calibration requirements at an early stage. This allows maintenance to be planned proactively and downtime to be avoided.

inforum test equipment management

Efficient test equipment management that withstands audits

With test equipment management, companies create a transparent, digital and audit-compliant basis for reliable quality management – precise, efficient and traceable at all times.

Fact check

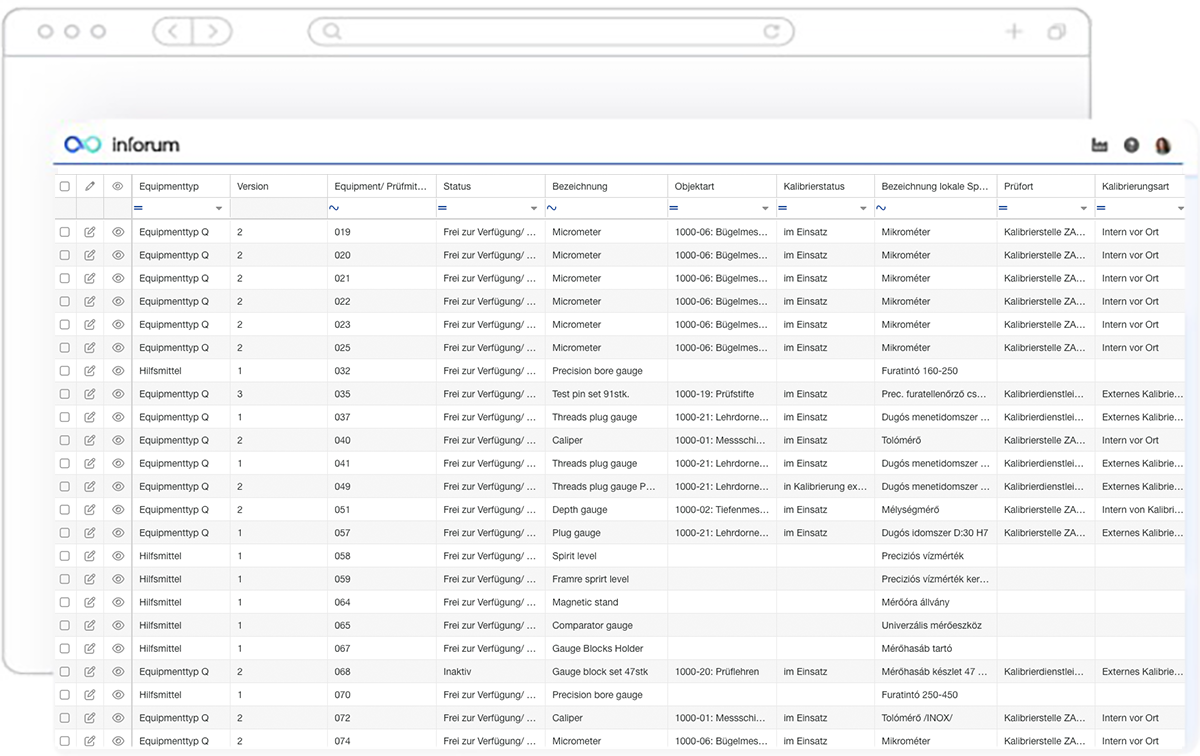

- Central management of all test equipment and associated device data

- Complete calibration documentation for verification and traceability

- Scheduled calibrations and safety checks according to standard specifications

- Automatic release after passing the test

- Compliance with legal and normative requirements (e.g. ISO, IATF)

- Automated monitoring systems for early detection of deviations

- Avoidance of breakdowns through proactive maintenance planning

- Increased process reliability and quality assurance throughout measuring equipment management

News from the newsroom

QM software from JAWA

Software for quality assurance and quality management | inforum from JAWA is the modular QM software.

Business AI

Unleash the full potential of your business data with inforum.ai – for more consistent productivity.

Process AI

Generative AI for the corporate process world. Discover our seamlessly integrated AI offering.