Software for

Control Plan

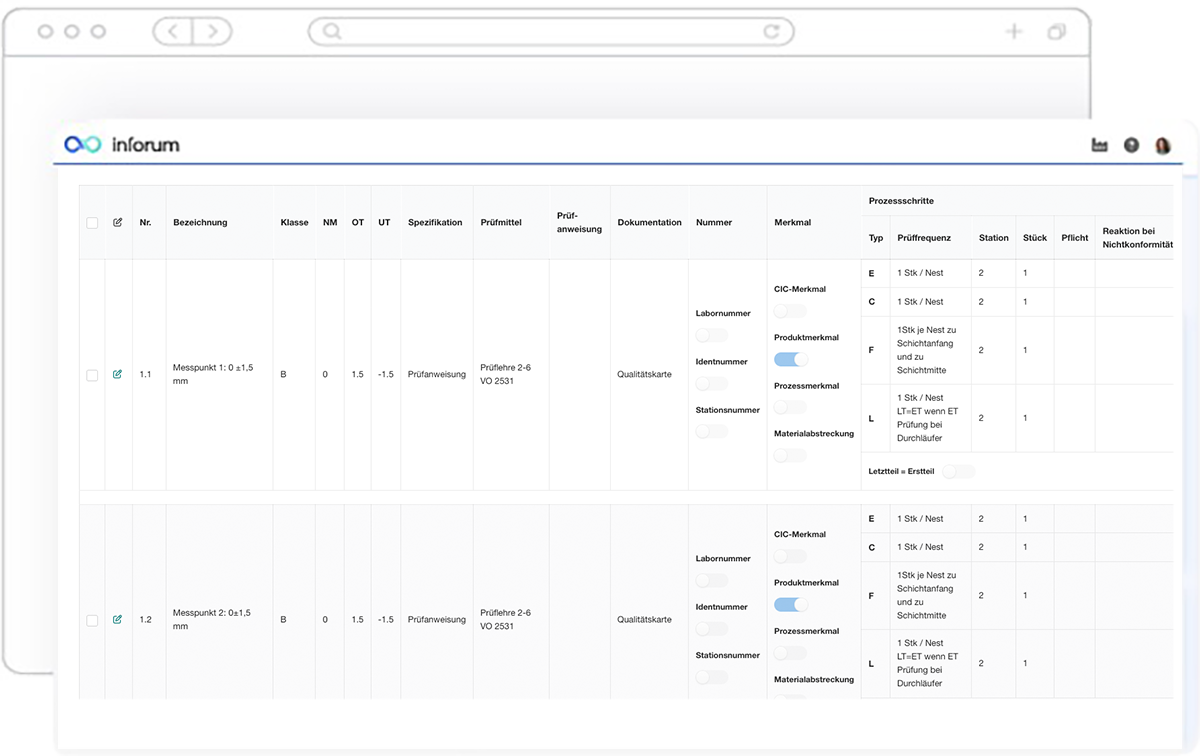

The Control Plan module enables centralized, digital planning and control of all quality-relevant inspection and control measures.

Standard-compliant safeguarding of products – directly on the line

The Control Plan module enables central, digital planning and control of all quality-relevant testing and control measures. It links production processes with quality requirements, ensures transparency and traceability and supports companies in the standard-compliant safeguarding of products – directly on the line, networked with the FMEA and always up-to-date.

inforum Conotrol Plan

Plan, check and ensure quality – digitally and efficiently

A digital control plan allows inspection and control measures to be centrally managed, easily updated and clearly displayed. Quality maps visualize all important characteristics, inspection points and process steps, while the production control plan ensures stable series production through clearly defined inspection procedures and responsibilities.

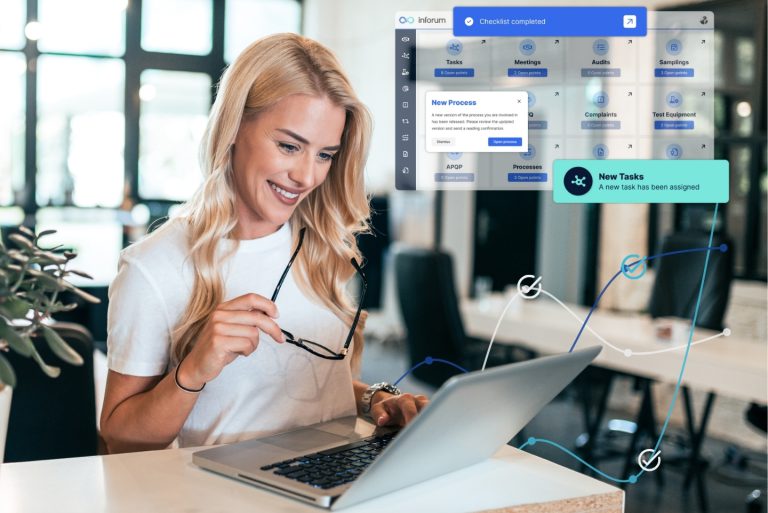

inforum enables mobile, intuitive and paperless inspection on the production line.

The digital test app from inforum

The digital inspection app enables inspections to be carried out and documented directly on the production line – mobile, intuitive and paperless. An integrated FMEA connection ensures that relevant characteristics and measures are automatically transferred and consistently processed.

inforum Control Plan

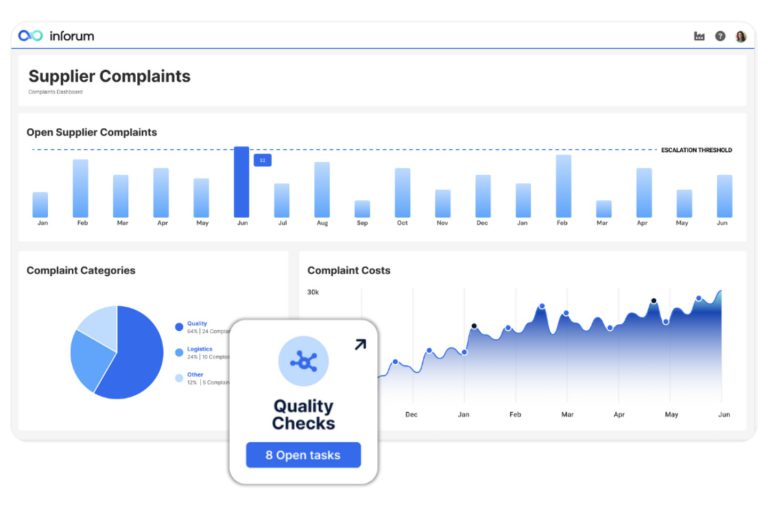

Tracking in real time

With this solution, changes are implemented in real time, audit and standard requirements are reliably fulfilled and quality assurance is made more consistent and efficient. Companies benefit from greater process reliability, reduced sources of error and seamless traceability – for greater quality, efficiency and customer satisfaction in series production.

Fact check

- Digital Control Plan: Central management and updating of all inspection and control measures.

- Quality map: Clear presentation of all quality-relevant characteristics and tests in the production process.

- Production control plan: Structured planning of process steps, tests and responsibilities for stable series production.

- Digital test app on the line: mobile, paperless execution and documentation of tests directly in production.

- FMEA connection: Automatic transfer of relevant characteristics and measures from the FMEA for consistent inspection plans.

- Real-time updating: Changes are controlled centrally and are immediately visible throughout the entire system.

- Audit and standard compliance: Support in meeting ISO, IATF and customer-specific requirements.

- Efficient quality assurance: end-to-end digitization reduces errors, saves time and ensures reproducible results.

- Seamless traceability: Complete documentation of all test and action histories.

News from the newsroom

QM software from JAWA

Software for quality assurance and quality management | inforum from JAWA is the modular QM software.

Business AI

Unleash the full potential of your business data with inforum.ai – for more consistent productivity.

Process AI

Generative AI for the corporate process world. Discover our seamlessly integrated AI offering.