Software for

FMEA

Creation of design, product and process FMEAs and associated control plans for risk assessment and quality assurance.

Recognize risks, avoid errors, ensure quality

Failure mode and effects analysis (FMEA) is a structured process for the early detection, evaluation and minimization of potential sources of error. It helps companies to systematically analyze risks and optimize products and processes in a targeted manner – for more quality, safety and efficiency.

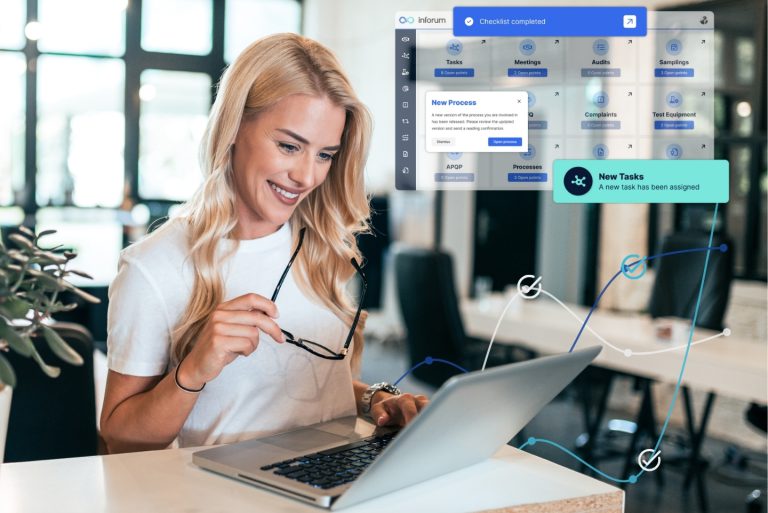

inforum FMEA Software

Derivation of suitable measures for risk reduction with FMEA software

FMEA supports development and production teams in breaking down complex systems into logical structures, analyzing functions, identifying possible types and causes of faults and evaluating their significance, occurrence and probability of detection. Suitable risk reduction measures are derived on the basis of these analyses and their effectiveness is checked and documented.

With inforum , it is possible to identify risks and derive sustainable measures.

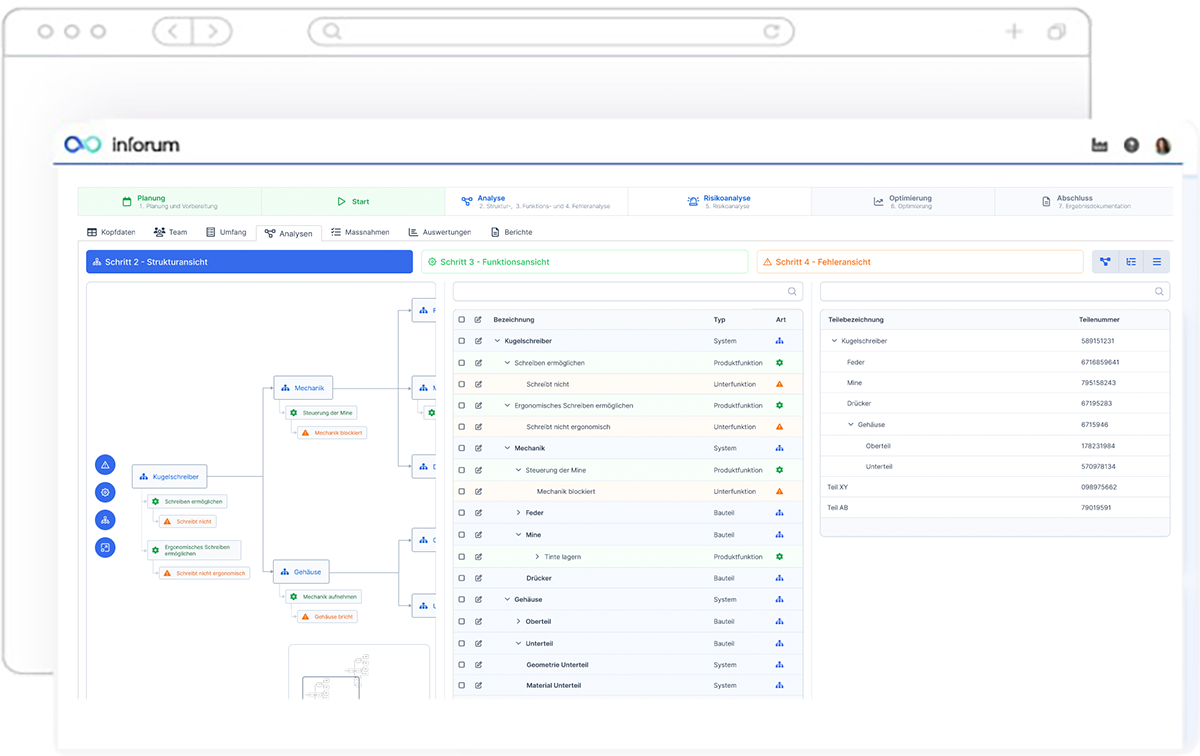

DFMEA, PFMEA & System-FMEA

The modular process comprises seven steps: planning and preparation, structural analysis, functional analysis, failure analysis, risk analysis, optimization and documentation of results. Different types of FMEA can be used: DFMEA evaluates product characteristics in the design, PFMEA analyzes production and assembly processes, and the system FMEA looks at complex systems with multiple components.

inforum FMEA

Minimize potential errors with FMEA software

The structured approach minimizes potential errors, prioritizes measures and ensures traceability. In this way, FMEA makes a decisive contribution to continuous improvement, increased product safety and long-term customer satisfaction.

Fact check

- Structured risk management: identify and evaluate potential sources of error at an early stage and minimize

- Standardized FMEA process: Seven clearly defined steps from planning to documentation of results.

- DFMEA, PFMEA & System-FMEA: Flexible use for product design, production processes and complex systems.

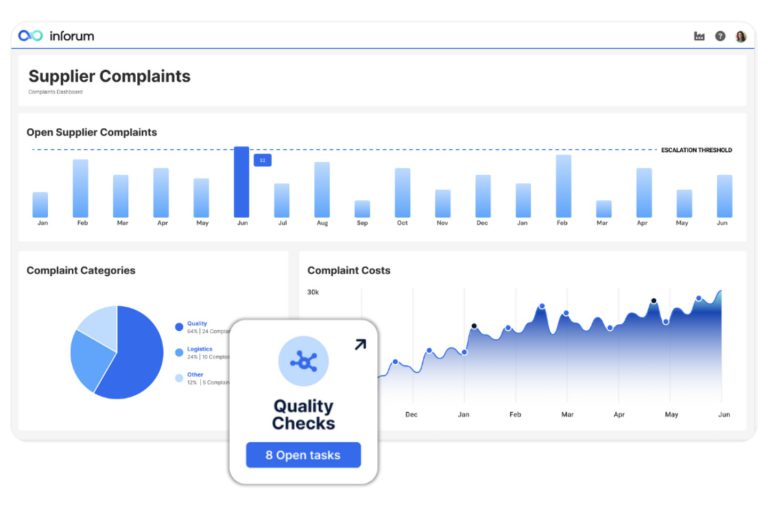

- Visualized analyses: structural analyses, function and error networks for a transparent presentation of correlations.

- Risk assessment according to VDA/AIAG: Evaluation according to significance, occurrence and detection for prioritization of measures.

- Integrated measures management: Derivation, tracking and reassessment of prevention and detection measures.

- Comprehensible documentation: standardized reports, risk matrices and audit documents available at any time.

- Continuous improvement: Iterative optimization of products and processes based on current analyses.

News from the newsroom

QM software from JAWA

Software for quality assurance and quality management | inforum from JAWA is the modular QM software.

Business AI

Unleash the full potential of your business data with inforum.ai – for more consistent productivity.

Process AI

Generative AI for the corporate process world. Discover our seamlessly integrated AI offering.